| | Engine at 7000 RPM - and a hell of a noise! |

Mark's VX powered car is a beast to drive. With much more power than our Supersport, it pops spits and bellows its way around airfields and tracks at tremendous speed! It got to the point where there was perhaps too much popping and spitting though. Slow driving at low speeds was not easy, and it was loud. Mark decided to get it looked at with a rolling road session, to see if any of these issues could be sorted out.

I took some pics!

Track'n'Road were recommended by a few prominent members of Blatchat. They are located north of Dartford just the other side of the Queen Elizabeth Bridge. Track'n'Road were recommended by a few prominent members of Blatchat. They are located north of Dartford just the other side of the Queen Elizabeth Bridge.

First things first - in order to properly do the figures, Mark's car first required a lambda probe. This goes in the exhaust manifolds, and here Steve is drilling a hole to weld a tapped collar into, to accept the sensor. First things first - in order to properly do the figures, Mark's car first required a lambda probe. This goes in the exhaust manifolds, and here Steve is drilling a hole to weld a tapped collar into, to accept the sensor.

Note the specially made protection!! This is to shield the bodywork and paint from sparks when Steve welds the collar into position. Note the specially made protection!! This is to shield the bodywork and paint from sparks when Steve welds the collar into position.

Obviously I was not looking at the sparks when I took this shot - that would be very bad for my eyes! Obviously I was not looking at the sparks when I took this shot - that would be very bad for my eyes!

New sensor in place. After the session this hole would have a blanking piece bolted into place. New sensor in place. After the session this hole would have a blanking piece bolted into place.

Car was now ready to be pushed into position... Car was now ready to be pushed into position...

...so it was! ...so it was!

Straps are used to pull the car down onto the rollers and hold it firmly in place. On a Caterham, care must be taken that the rear towing eye does not foul the rollers. Straps are used to pull the car down onto the rollers and hold it firmly in place. On a Caterham, care must be taken that the rear towing eye does not foul the rollers.

A fan blows air through the radiator and ensures the engine is not overheating. Obviously when on the rolling road the car is not actually moving through the air, hence the requirement for the fan. A fan blows air through the radiator and ensures the engine is not overheating. Obviously when on the rolling road the car is not actually moving through the air, hence the requirement for the fan.

Mark waits patiently - there would be a lot of this bit! Mark waits patiently - there would be a lot of this bit!

First stage was to balance the throttle bodies correctly - without doing this first any figures done later would not be any good. First stage was to balance the throttle bodies correctly - without doing this first any figures done later would not be any good.

The throttle bodies with air filter removed. Note the throttle linkage mechanism. Steve paid particular attention to this as his worst fear is a sticking throttle! The throttle bodies with air filter removed. Note the throttle linkage mechanism. Steve paid particular attention to this as his worst fear is a sticking throttle!

Steve balanced the throttles by ear - he used a stethoscope to listen to the throttle bodies as they operated and ensure that they were all operating equally. Steve balanced the throttles by ear - he used a stethoscope to listen to the throttle bodies as they operated and ensure that they were all operating equally.

Then it was onto the rolling road session itself. This basically involved running the car up through the rev range. At each stage (1000 revs approx) the figures were examined and adjustments were made as necessary. Then it was onto the rolling road session itself. This basically involved running the car up through the rev range. At each stage (1000 revs approx) the figures were examined and adjustments were made as necessary.

Steve in the car, other Steve at the laptop and Mark crouching above some very quickly revolving rollers! Steve in the car, other Steve at the laptop and Mark crouching above some very quickly revolving rollers!

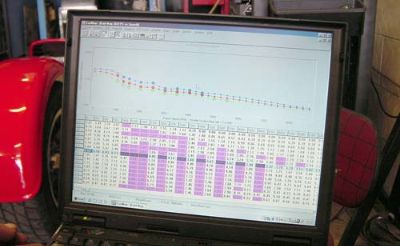

This picture shows the figures that had been adjusted in at this particular rev range. All the purple blocks on the screen are figures that *** has manually changed - it was to be along day!! This picture shows the figures that had been adjusted in at this particular rev range. All the purple blocks on the screen are figures that *** has manually changed - it was to be along day!!

This made a hell of a noise!! Not only was there the noise of Marks car at constant throttle for a couple of hours at various RPM, but the rollers themselves made a hell of a whine! This made a hell of a noise!! Not only was there the noise of Marks car at constant throttle for a couple of hours at various RPM, but the rollers themselves made a hell of a whine!

Mark still waiting patiently! Mark still waiting patiently!

Once the revs got to 5000rpm plus, Mark and I had to wear ear plugs! Once the revs got to 5000rpm plus, Mark and I had to wear ear plugs!

Steve was assisted by his colleague Steve throughout the session. Steve controlled the throttle whilst Steve played with the graph and figures! Steve was assisted by his colleague Steve throughout the session. Steve controlled the throttle whilst Steve played with the graph and figures!

At the higher end of the RPM range the exhaust manifold started to glow cherry red. At the higher end of the RPM range the exhaust manifold started to glow cherry red.

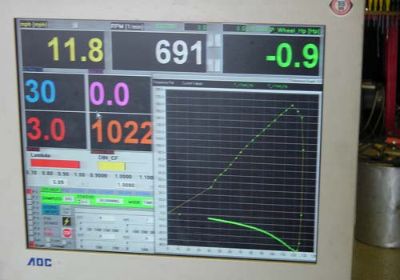

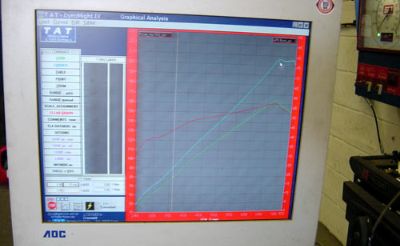

At the end of the session all that remained was a power run. This was a quick blast through the rev range to establish the cars final figures. It was much quicker than I expected, literally just a blast up to the rev limiter.

Final power curve. The conclusion was a figure of 208 bhp, but that this figure could be higher. The limiting factor was the fuel injectors. Higher spec injectors (I guess 'bigger') would mean that the engine could produce even more power easily - around 218bhp. Final power curve. The conclusion was a figure of 208 bhp, but that this figure could be higher. The limiting factor was the fuel injectors. Higher spec injectors (I guess 'bigger') would mean that the engine could produce even more power easily - around 218bhp.

Quite impressive to see these manifolds glowing like this - certainly explains why under bonnet temperatures can be so high. Quite impressive to see these manifolds glowing like this - certainly explains why under bonnet temperatures can be so high.

One of the final graphs. One of the final graphs.

No Mark - you can't sit there on the way home - you have to drive the tow car. No Mark - you can't sit there on the way home - you have to drive the tow car.

After the session was finished Mark went for a very quick test drive to see if he could tell the difference. We were relieved when he came back with a big grin, confirming that the car felt much much more driveable - a fact that has been confirmed in subsequent track days.

The popping and spitting had been massively reduced - this had the added bonus that the noise of the car had also been considerably reduced. At track day noise tests before the session Mark's car was recording levels of 102dB plus - after the session this has been reduced to about 98dB.

|