Our trusty 1.6 K-Series engine, with gearbox attached, is removed for the first time since we got the car. Ok - so it isn't clean, but so far it has been reliable! Our trusty 1.6 K-Series engine, with gearbox attached, is removed for the first time since we got the car. Ok - so it isn't clean, but so far it has been reliable!

Showing inlet manifold, coil, dip-stick. The black pipes to the right are part of the Apollo tank system. Red pipe is coming from the thermostat housing and eventually connects to the bottom of the radiator. Showing inlet manifold, coil, dip-stick. The black pipes to the right are part of the Apollo tank system. Red pipe is coming from the thermostat housing and eventually connects to the bottom of the radiator.

At the bottom of the picture above you can just make out the black foam that is the sump baffle. Above that, and under the red pipe you can also just make out the oil pick-up pipe. This normally sits bolted up under the sump baffle - the pipe end goes into a oil run, the bottom end looks a little like a tea strainer and sits in the sump where it can pick up oil.

Another view showing the plastic inlet manifold and plenum, and the crankshaft pulley on the front of the engine. Whilst on the M25 some time ago, the bolt that holds the crankshaft pulley onto the crankshaft fell off..... Another view showing the plastic inlet manifold and plenum, and the crankshaft pulley on the front of the engine. Whilst on the M25 some time ago, the bolt that holds the crankshaft pulley onto the crankshaft fell off.....

This is what the sump looked like when it was removed. Worryingly there was debris in it - this consisted of the broken end of our original dipstick, which we knew was in there.... This is what the sump looked like when it was removed. Worryingly there was debris in it - this consisted of the broken end of our original dipstick, which we knew was in there....

Some time ago, on a cold day, I was checking the oil level in the engine with the dipstick. I pushed the all plastic original dipstick back into the dipstick tube and was horrified when the end snapped off as the cold plastic refused to bend and slide into the curved tube! As the oil level in the Caterham sump is different (less than) the oil level found in a normal K-series engine, the dipstick had an extra 'groove' filed into the end, showing the revised level. This 'groove' was a weak point and it was at this point the dipstick broke. As I pushed the dipstick down, the end was pushed into the sump. I was reassured that it would be fine down here, with no danger of getting sucked up into the engine, and that I could remove it next time I removed the sump.

'New' dipstick with metal rod, replacing older all-plastic design. 'New' dipstick with metal rod, replacing older all-plastic design.

In the mean time I ordered a new dipstick from Caterham, to find that the design has since been changed to a metal rod with a plastic indicator moulded onto the end to indicate oil level. This new design cannot snap off. If you have the old all-plastic design, I would advise you order a new one from Caterham - only a few quid.

Amazingly and far more worryingly we also found 2 bolts sitting in the remaining oil - these were supposed to be holding the oil pick-up in position.... Amazingly and far more worryingly we also found 2 bolts sitting in the remaining oil - these were supposed to be holding the oil pick-up in position....

These bolts had somehow worked their way free and dropped into the sump. It was unlikely that they would be sucked up into the engine - the foam and tea strainer would stop that, but more worryingly it meant that there had been a chance that the oil pick-up pipe could have worked out of its hole (it was now not being held in position by anything!) which would have been catastrophic. We were very lucky!

Once the sump has been removed you can see the foam sump baffle. This stops the oil sloshing around in the sump any more than it has to, but as you can see it is prone to deteriation. Once the sump has been removed you can see the foam sump baffle. This stops the oil sloshing around in the sump any more than it has to, but as you can see it is prone to deteriation.

I had ordered some new foam - the new stuff is just like a scourer sponge, flexible and bright yellow. The old foam was anything but... I had ordered some new foam - the new stuff is just like a scourer sponge, flexible and bright yellow. The old foam was anything but...

Subjected to heat and oil, it had become brittle and broke into pieces as soon as it was touched. Pieces of it had already begun to block the oil pick-up pipe, which required a good clean. Subjected to heat and oil, it had become brittle and broke into pieces as soon as it was touched. Pieces of it had already begun to block the oil pick-up pipe, which required a good clean.

Having seen the state of the old foam I think we will change this part more often in the future, or perhaps even remove it all together. The new foam arrives as a simple rectangular sheet. It must be trimmed slightly when fitting, to allow bolts through it and to clear the oil pick-up pipe and dipstick slightly. The aluminum plate seen above is bolted up and holds the foam in position.

Looking up into the bottom end of the engine, with the sump foam removed. You can just make out the crankshaft. Top right of the bottom is the hole where the oil pick-up pipe locates, and the end of the dipstick tube. Looking up into the bottom end of the engine, with the sump foam removed. You can just make out the crankshaft. Top right of the bottom is the hole where the oil pick-up pipe locates, and the end of the dipstick tube.

When fixing the standard air filter to the K-Series plastic throttle body on the inlet plenum, do not over-tighten the jubilee clip. This can distort the plastic throttle body and cause the butterfly to stick. When fixing the standard air filter to the K-Series plastic throttle body on the inlet plenum, do not over-tighten the jubilee clip. This can distort the plastic throttle body and cause the butterfly to stick.

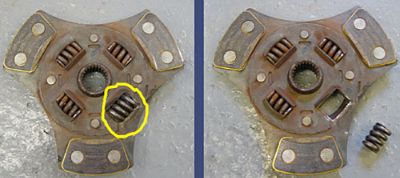

Not on our car, but one we were working on - a metal tab had broken off that retained one of the springs. Not on our car, but one we were working on - a metal tab had broken off that retained one of the springs.

Cracked clutch plate from mark's 2ltr VX car. Cracked clutch plate from mark's 2ltr VX car.

Close up detail of the crack. You can also see the distinctive pattern on the plate, I guess caused by a combination of heat and wear. Close up detail of the crack. You can also see the distinctive pattern on the plate, I guess caused by a combination of heat and wear.

Clutch release Bearing (CRB) problems are getting to be well documented, yet there does not seem to be any consitancy in their failures. For example, our car has done at least 70,000 miles and our CRB has never so much as sqeaked, yet people with less than 3000 miles are having CRB failures.

When we recently changed our flywheel and clutch we fitted a new CRB as a matter of course. We also removed another CRB from another car whilst helping Mark on another car. The picture below shows the only difference between what we think is a new(ish) CRB and an older one from our car...

The top CRB in this picture is from our 70,000 mile 1995 car - I assume it is the original as fitted in 95. The CRB below, although from another newer car, is identical to the new CRB we re-fitted to our car. Part numbers are the same - F-202994, but our older version has 'Germany' printed on it, where as the new one does not. The top CRB in this picture is from our 70,000 mile 1995 car - I assume it is the original as fitted in 95. The CRB below, although from another newer car, is identical to the new CRB we re-fitted to our car. Part numbers are the same - F-202994, but our older version has 'Germany' printed on it, where as the new one does not.

Is this significant? No idea, but it could just be possible that the newer CRB's are now made somewhere else, the Far East perhaps, and just maybe they are not of the same quality as the older, German made versions. This is entirely speculative, but you never know...

UPDATE - just after posting this section I got an anon email from a fellow Caterham owner who was also an employee of INA, which I reproduce here word for word - I have not corrected or changed anything, and I have no idea if it is right, wrong, indifferent etc but present it to you here for you to read and make your own conclusions!

Hello Angus,

Very interesting site about your all year used Caterham !I woul just like to inform you about the clutch release bearing of our compagny INA F-202994.The production was transfered some years ago to our brasilian plant so this is why the new bearings are not marked "Germany" but "BR" wich stands for "Brasil". Our Brasilian site offers the same quality levels as all our other plants in the world. This brasilian site is now producing all the clutch release bearings for INA Worldwide, some millions per year..., and is currently delivering hundreeds of differents clutch release bearings to the biggest automotive companies in the world.So do not be afraid, there is no problem to expect because of this production site transfer !This bearing is also the original part formerly purchased by FORD, it is not just an aftermarket copy of a competitor product.

I owned a Caterham and about the clutch bearing I would like to focuss on the fact that in general these bearings need a small preload against the clutch plate (30-40N) in order to prevent any relativ movement between the clutch finger and the ring of the bearing.Should there be too less preload, noise may occur, and also wear due to fretting corrosion because of micro-displacements between finger and bearing ring.

In extrem cases it can lead to bearing failure.In my Caterham 1.6K 1999 there was no system to realize this preload: Only the weight of the clutch Pedal ! On my car it seems just enough but I guess that with aging and increasing friction in the cable actuation or bad cable routing the preload resulting on the bearing and coming from the single pedal weight will decrease through the years and vary also from one car to another.But be careful not to have too much preload or you will continuously actuate the clutch and as you guess it leads to big problems also.

I mailed on that time about this on Caterham France but received as answer that they build the Sevens as recommended by Caterham UK ! That's all !I guess Caterham UK itself is may be not aware of that subtle condition to ensure a high life of the bearing. Would be nice if you could add some of my informations on your Web site !

Best regards, Anonymous INA Employee !

|